The industrial use of kaolin and kaolin powder grinder:

At present, kaolin in ceramics, rubber, plastic, leather, cement, refractory materials, chemical and other industrial and agricultural have wide application. Along with the high Ling soil mineral processing technology to further improve, kaolin application scope is wide. Kaolin is in nature a prevalent nonmetalliferous ore, used for the production of ceramics, refractory materials and a small amount of mixed plastic, rubber packing. As the the development of national economy various fields, people pay more and more attention to the depth of the kaolin processing, because it can not only get new materials with special performance, but also can improve the economic benefit.

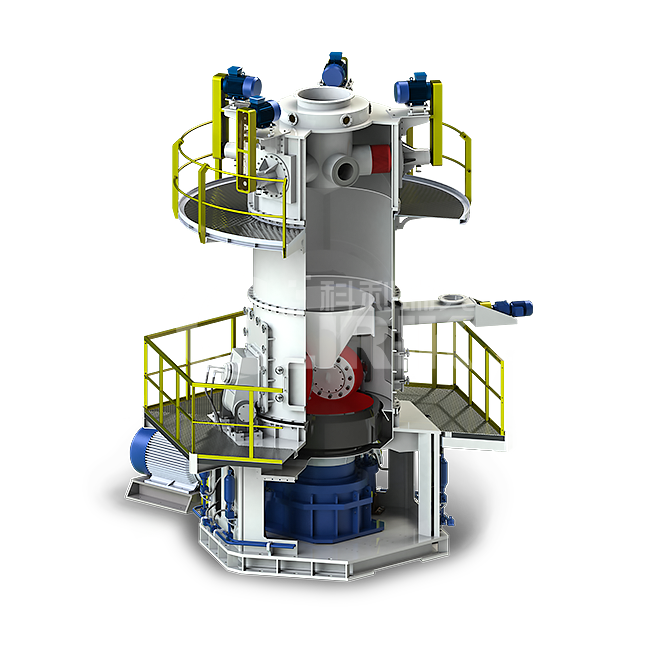

Introduce Of Kaolin powder grinder; Kaolin powder grinder series:

Kaolin powder grinder; Kaolin powder grinder series is for super-fine grinding materials with hardness less than 6 in Moh‘s scale and humidity less than 6 percent such as limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds. The granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.005mm), and the capacity (ton/hour) ranges from 0.4T/H to12T/H.

How does Kaolin powder grinder; Kaolin powder grinder series work?

1) After crushed by hammer crusher, the large materials become smaller pieces and are sent to the Kaolin powder grinder; Kaolin powder grinder series.

2) When the Kaolin powder grinder; Kaolin powder grinder series, the granulated materials are crushed and grinded by the rollers into particles below 47micron.

3) The high-pressure air blower constantly inhales air within the Kaolin powder grinder; Kaolin powder grinder series.

4) Along with the high speed airflow, micronized materials are brought to the classifier.

5) The qualified particles are screened and driven into the cyclone powder collector, finally exit from the discharging valve at the bottom;

6) A small proportion of the fine powders, with airflow, moving to the dust cleaner. Filtered clean air will be emitted from the air outlet of muffler in the end.

Technical data of Kaolin powder grinder; Kaolin powder grinder series:

There are five models of our Kaolin powder grinder; Kaolin powder grinder series: HGM80(HGM 8021), HGM90(HGM9024), HGM100(HGM10027), HGM100A( HGM10036),and the new type HGM125. The detailed specification and technical data of our Kaolin powder grinder; Kaolin powder grinder series are as below:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Note: This specification is just referencing, any changes are subject to the products.

Features and advantages of Kaolin powder grinder; Kaolin powder grinder series:

l、 High efficiency

Under the same finished final size and the same motor power, the capacity of Kaolin powder grinder; Kaolin powder grinder series is twice as much as jet mill, mixing grinder and ball mill.

2、Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

3、High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4、 High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≦5um.

5、Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

Shanghai clirik machinery co., LTD.

Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machine.please do not hesitate to contact us.

Phone: 0086-21-20236178;86-18918057603

Contact person: lily wang

Email:sales@clirik.com; lilywang@clirik.com

Online consulting: http://www.saico.net ;http://www.grinding-equip.com;

http://www.powder-grinder.com;http://www.powder-mill.net;http://www.fine-mill.net

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.