Application range: cement ultrafine powder processing, square stone processing, heavy crystal stone, grinding processing

Material: non-metallic mines such as square stone, marble, limestone, talc, heavy crystal, magnesia, raw lime, gypsum, slag, phosphate, etc

production capacity: 0.5-45t/h

The fineness of the finished product: 200-3000 meshes

Product features of Ultrafine Vertical Mill

With the rapid progress of the social economy, in the field of ultrafine powder processing, in the face of more and more ultrafine powder application requirements, traditional ultrafine powder processing equipment due to the characteristics of low general production capacity, has been difficult to meet market demand.

Low production capacity seriously restricts the development of modern ultrafine powder processing enterprises, in view of the current market demand, Shanghai CLIRIK combined with many years of mill production experience, introduced Taiwan and Germany ultra-fine vertical grinding technology, design, and development of a set of grinding powder, grading, transportation, secondary powder selection, finished products packaging in one of the new ultra-fine grinding equipment - CLUM series ultrafine vertical mill.

Its product fineness can reach 400-3000 meshes, breaking through the bottleneck of the low processing capacity of ultra-fine powder, after 5 years of grinding, CLIRIK ultrafine vertical mill has been built more than 30 ultra-fine powder production lines around the world.

CLUM series ultrafine vertical mill can be widely used in chemical, metallurgical, non-metallic ore, and other industries. Especially in the field of white non-metallic ore ultra-fine grinding processing, has an outstanding performance, provides high-quality fillers and additives for paper, coatings, plastics, rubber, PVC, inks, and other industries.

It can be widely used in square stone, marble, limestone, dolomite, heavy crystal, talc, kaolin, dolomite, silica ash, gypsum, long stone, leafstone, and other non-metallic ore large-scale ultra-fine dry powder processing.

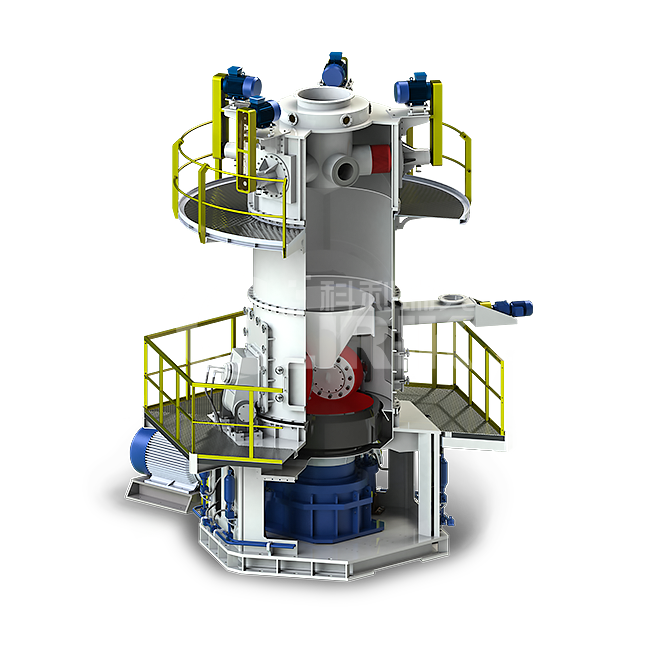

Structure composition of Ultrafine Vertical Mill

CLUM series ultrafine vertical mill mainly consists of electric motor, reducer, grinding wheel device, mill unit, pressurized device, powder picker, feed device, oil station, host, electronic control system and other parts.

1. Grinding wheel device: the main components of the crushing material, no power output, due to the friction in contact with the material and passive operation.

2. Milling device: the grinding area of the material, connecting the gearbox, turning itself.

3. Pressurized device: control the grinding wheel and mill disc clearance, to ensure that the grinding wheel pressure during grinding.

4. Powder picker: multi-machine head powder selection structure, the use of rotating centrifugal force principle to achieve continuous production of fine powder screening filtration work, is an efficient, energy-saving powder selection device.

Working principle of Ultrafine Vertical Mill

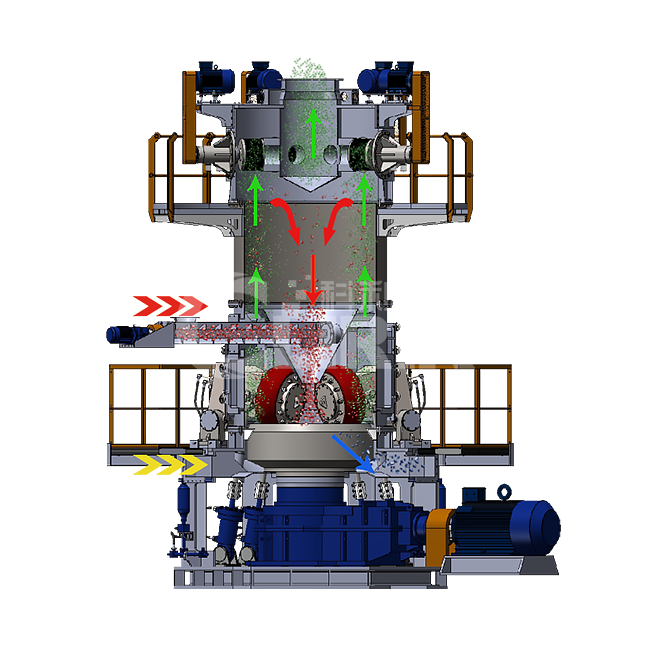

The main motor drives the mill to rotate through the gearbox, and the airflow generated by the high-pressure fan enters the main engine from the tuyere.

The material is sent to the center of the mill through a screw, and under the action of the centrifugal force of the mill, the material is dispersed from the center of the mill to the peripheral area, passing through the roller area on the mill.

Under the pressure of the roller, the large pieces of material are directly crushed, and the small particles are crushed, and then ground for further crushing until it is ground into powder.

The pulverized material continues to move to the edge of the mill until it is carried away by the strong airflow in the air inlet. The materials in the airflow flow through the separator, and the coarse particles fall back to the mill for re-grinding. Qualified powder passes through the powder selection system with the airflow and is collected by the dust collector.

Advantages of Ultrafine Vertical Mill

• Energy efficient

Technical parameters of Ultrafine Vertical Mill

|

Main configuration and production |

|||

|

Model |

CLUM1425 |

CLUM1632 |

CLUM1736 |

|

Plate Diameters(mm) |

1400 |

1600 |

1700 |

|

Number of rollers(pieces) |

3 |

3 |

3 |

|

Number of classifier(pieces) |

5 |

7 |

7 |

|

Power of classifier(Kw) |

5X15 |

7X15 |

7X(15~18.5) |

|

Main unit power (Kw) |

250 |

315 |

355 |

|

Blower power(Kw) |

200 |

250 |

315 |

|

Feed size (mm) |

<10mm |

<10mm |

<10mm |

|

Moisture of feeding material |

<3% |

<3% |

<3% |

|

Less than2μm=34%output(t/h) |

11-14 |

13-17 |

15-19 |

|

Less than2μm=46%output(t/h) |

7-8 |

9-10 |

11-12 |

|

Less than2μm=60%output(t/h) |

3-4 |

/ |

/ |