Barite and the use of Barite powder after processing by powder grinder:

Barite is the common minerals barium, its composition is barium sulfate. Barite is a kind of very important non-metallic mineral raw materials, has a wide range of industrial uses:1. The drilling mud weighting agent. 2. Lithopone pigment. 3. All kinds of barium compounds. 4. Packing industrial barite. 5, cement industrial mineralizer. 6. Prevent ray cement, mortar and concrete. 7. Road construction: at present, the heavy road construction equipment tires have partially filling barite, in order to increase the weight, which will help fill area compaction.

Other: barite and oil mixed on the cloth base on manufacturing cloth; Barite powder used for refining kerosene; In the pharmaceutical industry in gastrointestinal contrast agent; Still can system pesticide, the leather making, the system of fireworks, etc. In addition, barite is also used for extraction metal barium, used as a television and other vacuum tube getter, binder. Barium and other metal (aluminum, magnesium, lead, calcium) made of alloy, used for bearing manufacturing.

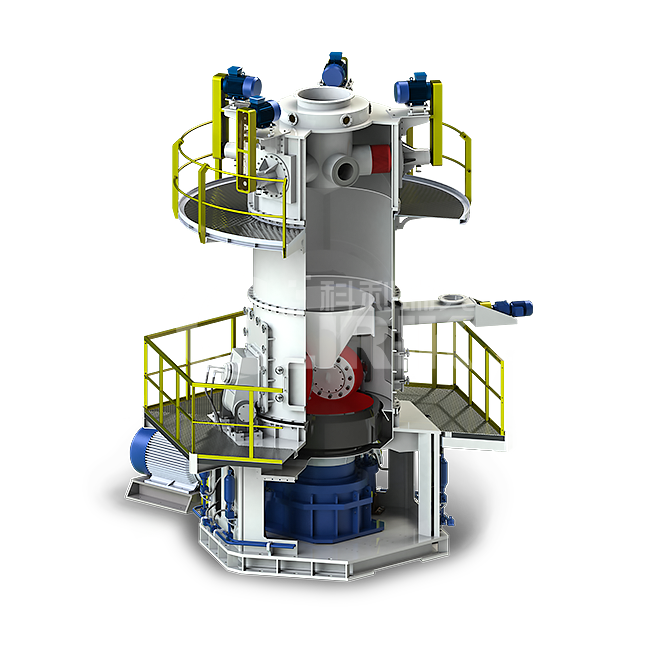

Introduce of Barite powder grinder; Barite powder grinder series:

Barite powder grinder; Barite powder grinder series is for super-fine grinding materials with hardness less than 6 in Moh‘s scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds. The granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H.

The main specification of Barite powder grinder; Barite powder grinder series:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Note: This specification is just referencing, any changes are subject to the products.

Features and advantages of Barite powder grinder; Barite powder grinder series:

● High Efficiency

Under the same finished final size and the same motor power, the capacity of Barite powder grinder; Barite powder grinder series is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

● Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

● High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

● High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

●Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

●Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.