Specifications

Powder surface modifying machine, GCC powder, coating machine, high efficiency, low consumption

Powder surface machine is applicable to modifying various materials. It can reach excellent surface modifications for such materials as heavy / light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesium-hydroxide bariumcarb, illite claystone and pyrophylite, hexagonite and etc.

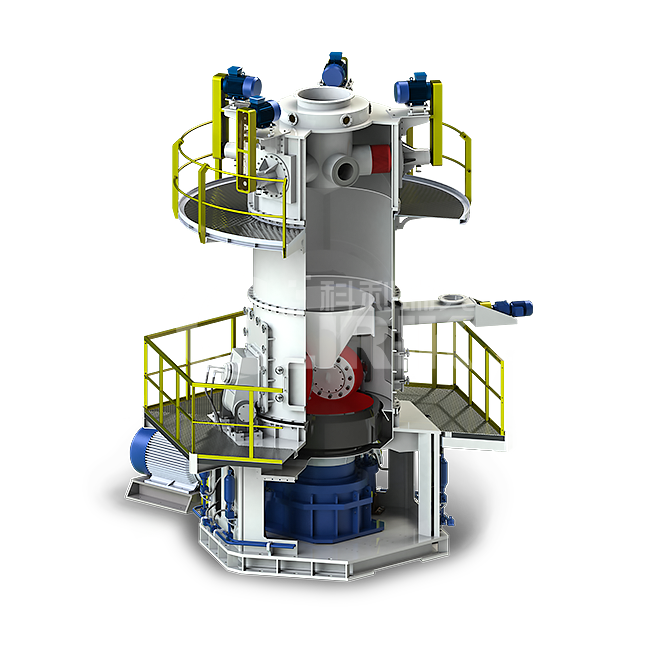

Structure and Special feature of powder surface modifying machine

The machine is made of following parts:

a. Hopper: materials enter into hopper from silo or bags. Humidity of feeding materials should be less than 0.5%.

b. Conveying device: With double screws and adjustable speed to ensure the stability of material flow

c. Agent adding system with temperature control:

Automatic temperature controller is able to control the melting temperature freely, which is suitable for various modifying agents in both solid and liquid form.

d. Main machine: consisting of 3 modifying rollers in triangle form, compact design, high efficiency and stable running.

e. Cyclone dust collector: Diffusion type

f,Impulse type bag dust collector: New generation pleat filter, with the advantage of little space, large filtration area, high dust removal efficiency and easily cleaning.

Main Technical Parameter of powder surface modifying machine

|

Type |

SLG-3/300 |

SLG-3/600 |

|

Main unit power (KW) |

18.5KW x 3 |

37KW x 3 |

|

Blower power (KW) |

5.5KW |

15KW |

|

Main shaft rotating speed (RPM) |

4500 |

2700 |

|

Output capacity (kg/h) |

500-1500 |

2000-4000 |

|

Size (MM) |

5250X1800X5600 |

7218x3680x6450 |

Performance and features of powder surface modifying machine

a) Continuous operation, large capacity, suitable for industrialization production in various scales.

b) High use and less consumption of modifying agent, high covering and active index of power, energy saving.

c) Both modifying and dispersion function, suitable for any fine materials, special active effect for material with small proportion and big cubage weight like white carbon, mica powder and talcum powder.

d) Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape.

e) Running at vacuum, air tight, no dust leakage, no pollution, good operation condition, low labor intensity.

f) Operating in heat and cold conditions, no additional heating or cooling system required, easy operation

g) Independent fluid and non-fluid agent adding system for continuous, stable and even operation.