For quartz sand, everyone is familiar with it and is often used in glass, ceramics, chemicals, water treatment filter materials and other fields. Quartz sand is a quartz granules made of crushed sand and has been promoted and applied in the mechanism sand industry in recent years. How does the small quartz sand production line design and how much is the equipment price?

Quartz sand is a new type of stone that is artificially synthesized by more than 90%of the quartz crystals plus resin and other trace elements. It belongs to non -metallic minerals and is a hard, abrasion -resistant and stable silicate mineral. The hardness is about 7, the density is 2.65, and the common specifications are 0.5-1mm, 1-32mm. According to its nature, it is recommended to choose equipment such as jaw crusher, cone crusher, impact sand making machine and other equipment. At the same time, the production requirements, feeding size and site conditions are considered. The process process of the specific small quartz sand production line is as follows:

Quartz sand production line process process:

Vibration Given Machine → Jaw Crusher → Conevant Crusher → Institution Sand Machine → Vibration Siege → Sand washing machine → conveyor

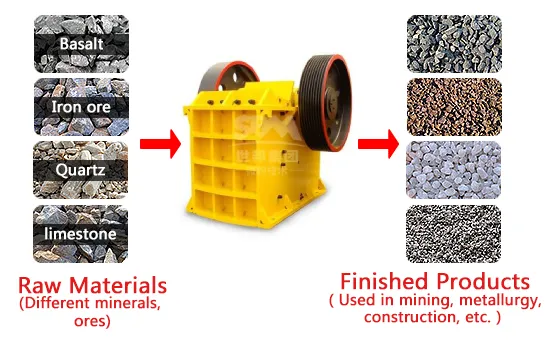

Jaw Crusher:

As a coarse crusher, by squeezing the crushing working method, the crushing cavity is deep, there is no dead zone, and the granularity of the raw material does not need to worry about the blocking material. At the same time, the discharge port adjustment method is different from the traditional plug -in adjustment method. The wedge adjustment of the discharge port is reduced to reduce the labor intensity and stop time of the workers. The granularity adjustment range of the finished product is 10-350mm and the particle size is uniform, which helps to deal with the second stage.

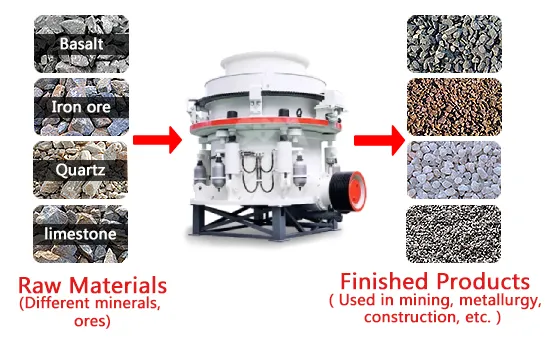

Cone crusher:

According to the hardness of quartz sand, the cone breakthrough not only meets the needs of the use, but also has strong wear resistance resistance to the loss of hard materials when dealing with hard materials, solves the problem of high operating costs in the later stage, and increases its service life. Adjust the discharge port and adjust the operation through hydraulic motors, the range is 3-60mm, that is, 12 and 13 stones. It also adopts a layer of crushing cavity design. Most of the finished products are cubic structures, which largely reduce needle -shaped materials.

Impact sand making machine:

The combination of two working methods of stone beating stones and stone beating iron. The particle size of the finished product is 0.25-0.5mm (coarse sand, medium sand, fine sand). Even if the high -hardness material is treated, the use of damaged parts is long. With a combined toss head, the peripheral board can turn around and reduce the operating cost.

What is the price of small quartz sand production line equipment?

For the price of small quartz sand production line equipment, according to the current market understanding, it is generally about hundreds of thousands to one million, and the difference is still large. This is because equipment configuration, model selection, solution design and other More, the quotation will be different.

What is the price of specific small quartz sand production line equipment? You can directly consult and understand online, and you can learn more about some other information in detail. CLIRIK has been producing and selling factories for many years, eliminating middlemen, and its cost performance is higher. You can rest assured of our equipment quality, and you are welcome to go to the factory to inspect the real machine at any time. After sales, it is also more guaranteed. We provide services such as installation, debugging, operation guidance.