We are Shanghai Clirik Machinery, who specialized in supplying all kinds of Industrial Powder Grinders. Especially Ultrefine Powder Grinder is the most representative machine of Industrial Powder Grinders, but we need to keep our eyes on many things when operating Industrial Powder Grinder, such as Ultrafine Powder Grinder. We must pay attention to safety of the equipment, so as to extend the service life of Industrial Powder Grinder, which also can increase its productivity.

We can take measures to add a lubricant in time to extend the service life of Industrial Powder Grinder. In addition to oil and grease, commonly used lubricants are quintana lubricant and gas lubricants.

Among them, the use of lubricants to extend the life of Industrial Powder Grinder is the most common. There are mineral oil, synthetic oil, animal oil. Grease thickening agent is added in lubricating oils and lubricants formed finger, also called butter. Lubricating inside the Industrial Powder Grinder can be divided into two kinds: centralized lubrication and dispersed lubrication. Dispersed lubrication is separately lubricating individual components, and this lubrication may be inter-segment or continuous. Lubricant is not only played an important role in the Industrial Powder Grinder, but also has a significant role in other models of equipments.

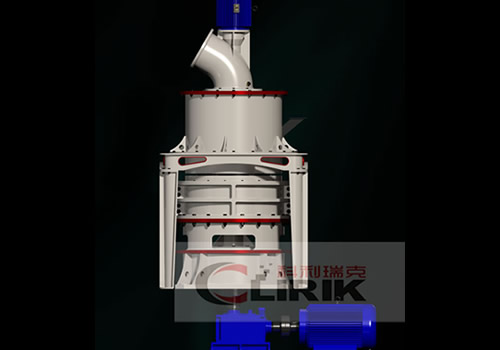

As a professional Industrial Powder Grinder manufacturer, Shanghai Clirik supply many kinds of Powder Grinders, including high pressure powder grinder, high pressure roller powder grinder, R Series Raymond powder grinder, Ultrafine powder grinder, and so on. If you want to know more about our Industrial Powder Grinder, please connect with me!