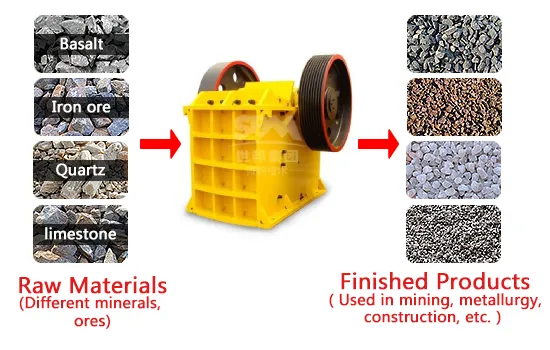

Jaw crusher is a commonly used crushing equipment in mining, smelting and other industries. It has the characteristics of large crushing ratio, uniform product particle size, simple structure and reliable operation. However, during use, due to the inhomogeneity of materials and the influence of other factors, uneven product particle size may occur. At this time, the jaw crusher needs to be adjusted to ensure its normal operation and production quality. This article will introduce how to adjust the thickness of the jaw crusher.

First, we need to understand the structure and working principle of the jaw crusher. Jaw crusher is mainly composed of jaw plate, machine body, adjustment mechanism and transmission device. When working, the material enters the crushing cavity through the feed port, is crushed under the movement of the jaw plate, and is then discharged from the discharge port. The adjustment mechanism can adjust the opening and spacing of the jaw plates to control the particle size of the product.

Different adjustment methods are required for different materials and production requirements. Generally speaking, there are several methods to adjust the thickness of the jaw crusher:

1. Adjust the regulating mechanism

The adjustment mechanism is an important part of the jaw crusher. It can control the particle size of the product by adjusting the opening and spacing of the jaw plates. According to the different materials and production requirements, the nut on the adjustment mechanism can be turned to change the opening and spacing of the jaw plates, thereby adjusting the particle size of the product. It should be noted that the position and adjustment range of the adjustment mechanism have certain restrictions and cannot be adjusted at will, otherwise it will affect the normal operation of the equipment and production quality.

2. Adjust the eccentricity

Eccentricity is another important factor affecting the particle size of jaw crusher products. It can affect the particle size of the product by changing the swing trajectory of the movable jaw. If the eccentricity is too small, the product particle size will become finer; if the eccentricity is too large, the product particle size will become coarser. Therefore, the eccentricity needs to be appropriately adjusted according to the different materials and production requirements. It should be noted that adjusting the eccentricity requires a certain technical level and experience, and cannot be adjusted at will, otherwise it may affect the normal operation of the equipment and production quality.

3. Replace jaw plates with different specifications

The jaw plate is the main working part of the jaw crusher. Its specifications and quality will affect the particle size of the product. If the currently used jaw plate cannot meet production requirements, jaw plates of different specifications can be replaced to adjust the particle size of the product. It should be noted that when replacing the jaw plate, you need to consider the nature, hardness and other factors of the material, and select the appropriate jaw plate specifications and quality to ensure the normal operation of the equipment and production quality.

In short, adjusting the thickness of the jaw crusher requires different methods according to different materials and production requirements. During the adjustment process, factors such as the structure, working principle, and material properties of the equipment need to be taken into consideration to select an appropriate method for adjustment. At the same time, it is necessary to keep the equipment clean and maintained, regularly check the operation of the equipment and the wear and tear of components, and promptly replace damaged components and perform maintenance to ensure the normal operation and production quality of the equipment.