Copper ore is the ore mined from copper ore, which can be processed into copper concentrate or copper ore with higher copper content. Copper concentrate needs to be smelted and extracted to become refined copper and copper products.

Types of copper ore: mainly natural copper, chalcopyrite, bornite, chalcocite, azurite, copper blue, etc. Application areas: Copper ore is mainly used in the metallurgical industry as a raw material for the metallurgical industry.

Copper ore processing and production process

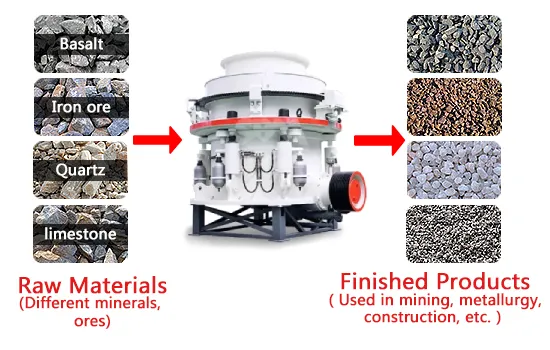

The copper ore processing and production process mainly includes three processes: crushing, grinding and beneficiation.

In the crushing process, the three-stage closed-circuit crushing is more modern and suitable for the crushing of high-hardness copper ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency.

In the grinding process, the two-stage one-closed grinding is an efficient grinding process, which can make the copper ore grind more fully.

Among the beneficiation processes, the most successful new processes that have appeared in recent years are mainly the mixed flotation process.

>>Stage 1: crushing and screening

The large copper ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing.

The coarsely crushed copper ore is screened by a vibrating screen, and then sent to a single-cylinder hydraulic cone crusher (middle crushing) by a belt conveyor for secondary crushing.

The medium crushed copper ore material is sent to the multi-cylinder hydraulic cone crusher for fine crushing.

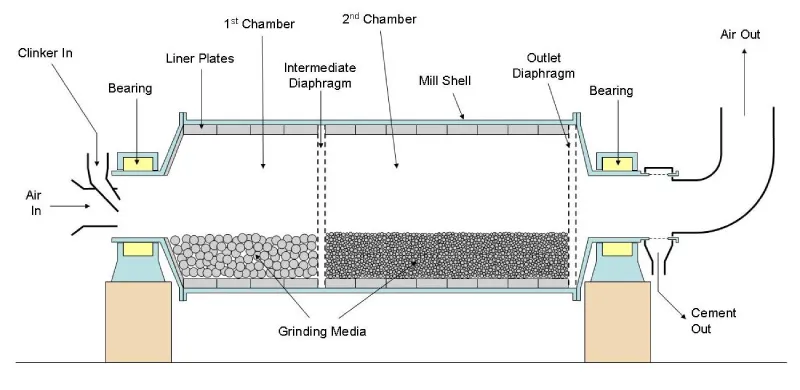

>>Stage 2: Grinding

The 0-12mm copper powder sieved by the vibrating screen is evenly sent to the ball mill for grinding, and sieved by the spiral classifier, and those that do not meet the requirements are sent to the ball mill to continue grinding.

Ball mill is a more commonly used and efficient grinding equipment. It is suitable for grinding ore such as iron ore, gold ore, copper ore and lead-zinc ore and other metal beneficiation, used to grind the ore below 0.075mm for subsequent beneficiation process.

According to different discharge methods, it can be divided into grid type and overflow type. The grinding methods can be divided into dry and wet grinding methods.

>>Stage 3: Magnetic selection

The copper powder that meets the requirements is sent to the flotation machine for mixed flotation.

Magnetic separator

Magnetic separator is a device that uses appropriate strength of magnetism to separate iron powder in powdery granules. Magnetic separator is widely used in beneficiation, suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size below 3mm.

It is also used for iron removal of coal, non-metallic minerals, building materials and other materials. It is one of the most widely used and highly versatile models in the industry.

>>Stage 4: Drying

The copper powder can be obtained by sending the obtained copper powder into a dryer for drying.

Dryer

Dryer is a commonly used equipment in mines after beneficiation, including a rotating drum, the inner drum is driven by a belt, and there is hot air around the drum for evaporating water. The drying drum adopts the principle of forward and reverse rotation of the drum to achieve the effect of drying the items without winding, so that the moisture in the material can be removed.