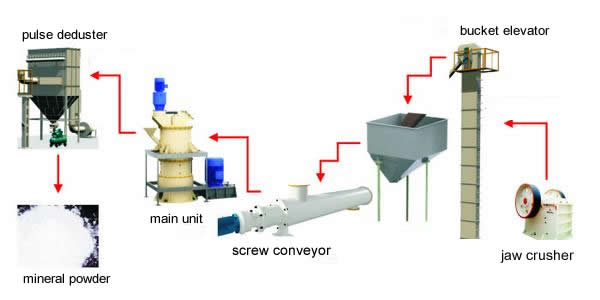

The ore milling production line is an independent production line for the production and processing of non-metallic minerals. Common non-metallic minerals include lime, gypsum, limestone, etc., which are suitable for various building materials, chemical, chemical, mining, pharmaceutical, construction and other industries. It is one of the indispensable projects for the rapid development of the domestic powder industry. The whole grinding production line can be generally divided into steps of crushing, conveying, grinding, and powder selection. Therefore, the grinding machine alone cannot complete the whole grinding work, and other equipments are needed. So what equipment does the entire ore milling production line need to configure?

1. A crusher

It is recommended to use a jaw crusher here. Because the jaw crusher can be said to be the core equipment in the mine crusher industry, it is suitable for coarse and medium crushing operations of various soft and medium hard ores. It is a very good choice for the initial break of ore.

2. Feeding equipment

Bucket elevators and vibrating feeders. The bucket elevator is a transportation device suitable for a variety of granular ore clay, sand powder ore clay lifting from the bottom up. The main function of the vibrating feeder is to ensure that the material enters the crusher evenly, avoiding the phenomenon of congested feeding and breaking the material.

3. Mill equipment

The mill is the core equipment in the ore milling production line - powder preparation equipment. Among them, Raymond mill is a more commonly used mill. At the same time, with the strict requirements on the fineness of various ore powders in the market, new high-efficiency milling equipment such as ultra-fine grinding mill and micro-grinding began to be put into use.

4. Separator

The classifier is a classifying device for ore powder, which can effectively send the fine powder to the collecting device to facilitate the final product packaging.

5. Dust removal equipment

The ore milling production line will inevitably generate dust during the production process. At this time, the dust collector plays a good role in dust removal and reduces the pollution during the milling production process to a small extent.