Introduce Of Illite powder grinder series;Illite powder grinder supplier:

the use of lllite:

Illite is a common kind of clay minerals, produced in pelite, usually weathering by white micaand potassium feldspar, or formed by the alteration of other minerals. It is also the middle transitional mineral to the formation of other clay minerals. Pure illite clay is white, butbecause it contains impurities,which was dyed yellow, green, brown and other colors.Underside cleaves completely. Mohs’s hardness is 1~2. Specific gravity is 2.6~2.9.

Illite has potassium-rich, high aluminum, low iron and smooth, bright, delicate, heat resistance etc. superior chemical and physical properties. Illite clays can serve as novel ceramic raw materials, fluxes of heat resistant cylinders and cosmetic or plastic packing. Besides, it can be adsorption of cesium in nuclear waste processing to exert radiation effects. Pure white illite can replace kaolin as paper coating, as well as for the production of car shell sprayed materials, welding electrodes, and so on.

Illite has wide industrial use, can be used to produce potash, advanced coatings, fillers, ceramic parts, advanced cosmetics, soil conditioning agent skeleton ingredients, high-rise building, poultry feed additive and cement batching, nuclear industrial purification of pollution and environmental protection. Trace element can be made of the outer coating of space shuttle.

Especially in three industries of paper making, cosmetics, ceramic, illite has a great value.

Scope of application of the Illite powder grinder series;Illite powder grinder supplier:

Illite powder grinder series is mainly applied to non-inflammable, non-explosive and brittle materials with Mohs hardness under seven, such as calcite, chalk, limestone, dolomite, carbon black, bentonite, kaolin, talc, mica, magnesite, illite,pyrophyllite , roseite, sea-foam, attapulgite , rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, kalium ore, pumice etc. totally more than 100 kinds of materials.Illite powder grinder series finished product fineness: 325 mesh ~ 3000mesh.

Finished powder products are in the 325meshs -3000meshs, and yield can be up to 0.7-7.5 tons per hour. Illite powder grinder supplier in shnghai is Clirik.There are four types of Shanghai Clirik Illite powder grinder series. they are HGM80, HGM90, HGM100, and HGM100A.

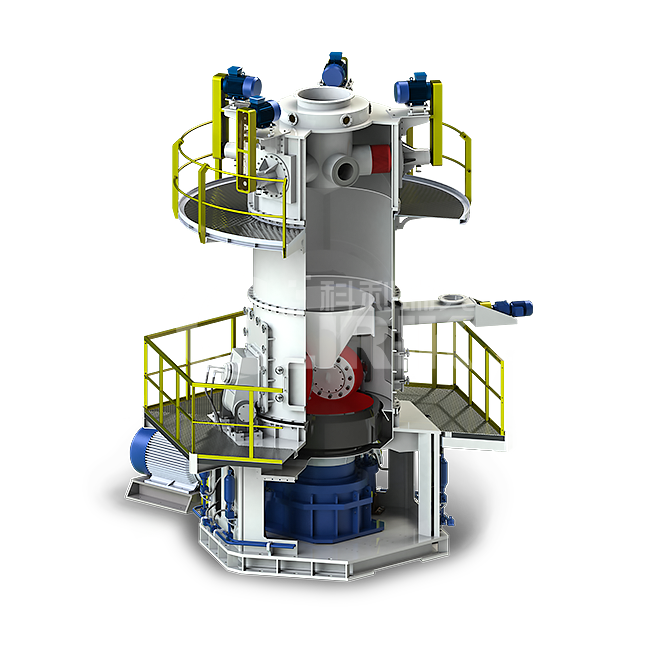

Illite powder grinder supplier(industrial grinding machine) devices:

Illite powder grinder series (industrial grinding machine) mainly consist of hammer crusher , micro powder main unit, Frequency conversion classifier, powder collector, pulse dust cleaner,high pressure positive blower, air compressor, muffler, electrical apparatus control system, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

Model and technical data of Illite powder grinder series :

|

Model |

HGM80 |

HGM90 |

HGM100 |

HGM100A |

HGM125 |

|

Ring Diameter(mm) |

800 |

900 |

1000 |

1000 |

1250 |

|

Ring Number/pcs |

3 |

3-4 |

3-4 |

4 |

4 |

|

Roller Number/pcs |

21 |

24-32 |

27-36 |

27-36 |

40-44 |

|

Main Shaft Speed/r. p. min |

230-240 |

200-220 |

180-200 |

180-200 |

135-155 |

|

Input Size/mm |

≦15 |

||||

|

Finished Size/um |

5-47(325-3000) |

||||

|

Capacity t/h |

0.4-4.5 |

0.4-5.5 |

0.4-6.5 |

0.4-7.5 |

0.7-10 |

|

Outlet Size L*W*H/m |

13.9*4*6.2 |

14.7*4.8*7.2 |

18*4.6*8.6 |

18*4.6*8.6 |

14*9*10 |

Note:This specification is just referencing, any changes are subject to the products.

1. High efficiency

Under the same final size and power, the product capacity of Illite powder grinder series is twice than jet mill and agitation mill.

2. Longer lifetime of spare parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical shaft impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability:

There are no rolling bearings and bolts in grinding cavity, so problems caused by bolts shedding or wear of bearings and seal components will never happen.

4. High fineness of products

The product fineness can reach D97≤5μm.

5. Environment friendly

The application of pulse dust collector and muffler reduce the pollution and noise of the dust, which has reached national environment protection standard.