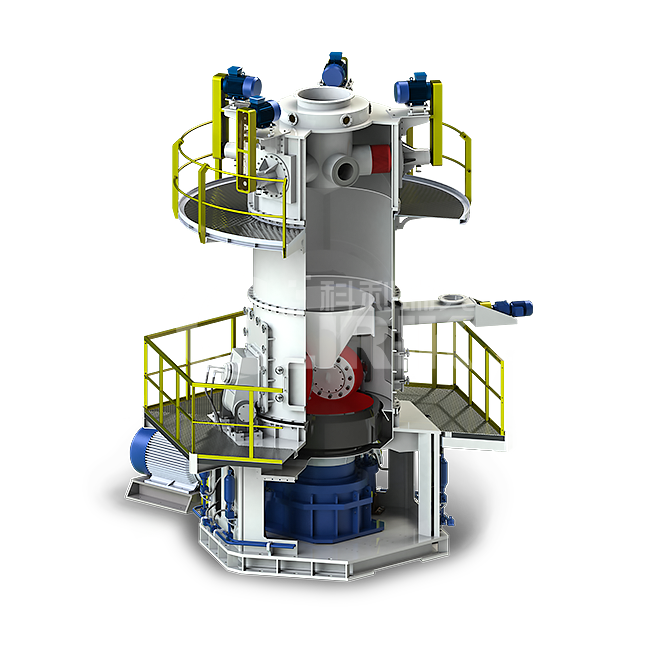

Introduce Of Talc powder grinder;Talc powder grinder series:

Talc powder grinder;Talc powder grinder series is a new type machine to grind Talc Stone into super thin Powder.The final Powder size can be from 5micron to 47micron as per 97% passing rate.We are a leading manufacturer of Talc powder grinder;Talc powder grinder series in Shanghai, China. As a professional manufacturer of this powder grinder machine, we have been in this line for many years, and now our products spread over the world for the good quality and competitive price.

Talc powder grinder;Talc powder grinder series is mainly applied to non-inflammable, non-explosive and brittle materials with Mohs hardness scale under seven, such as calcite, chalk, limestone, dolomite, carbon black, bentonite, kaolin, talc, mica, magnesite, illite, pyrophyllite , roseite, sea-foam, attapulgite , rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, kalium ore, pumice etc. totally more than 100 kinds of materials.Finished powder products are in the 325meshs -3000meshs, and yield can be up to 0.5-12 tons per hour. There are five types of Shanghai Clirik HGM series manufacture powder grinder, they are HGM80, HGM90, HGM100, HGM100A and HGM125.

Talc powder grinder;Talc powder grinder series devices:

Model and technical data of Talc powder grinder;Talc powder grinder series

|

Model |

HGM80 |

HGM90 |

HGM100 |

HGM100A |

HGM125 |

|

Ring Diameter(mm) |

800 |

900 |

1000 |

1000 |

1250 |

|

Ring Number/pcs |

3 |

3-4 |

3-4 |

4 |

4 |

|

Roller Number/pcs |

21 |

24-32 |

27-36 |

27-36 |

40-44 |

|

Main Shaft Speed/r. p. min |

230-240 |

200-220 |

180-200 |

180-200 |

135-155 |

|

Input Size/mm |

≦15 |

||||

|

Finished Size/um |

5-47(325-3000) |

||||

|

Capacity t/h |

0.4-4.5 |

0.4-5.5 |

0.4-6.5 |

0.4-7.5 |

0.7-10 |

|

Outlet Size L*W*H/m |

13.9*4*6.2 |

14.7*4.8*7.2 |

18*4.6*8.6 |

18*4.6*8.6 |

14*9*10 |

Note:This specification is just referencing, any changes are subject to the products.

1. High efficiency

Under the same final size and power, the product capacity of Talc powder grinder;Talc powder grinder series is twice than jet mill and agitation mill.

2. Longer lifetime of spare parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical shaft impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability:

There are no rolling bearings and bolts in grinding cavity, so problems caused by bolts shedding or wear of bearings and seal components will never happen.

4. High fineness of products

The product fineness can reach D97≤5μm.

5. Environment friendly

The application of pulse dust collector and muffler reduce the pollution and noise of the dust, which has reached national environment protection standard.