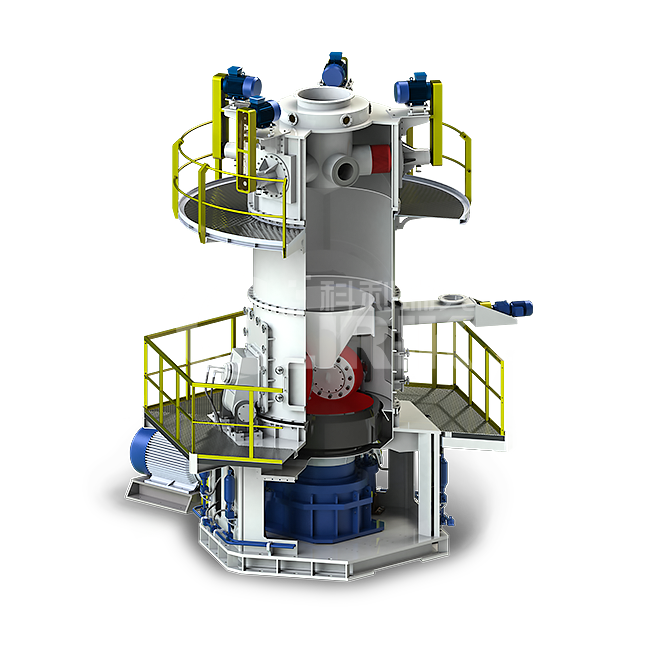

Basalt powder grinder;Basalt micro powder grinder, powder milling machine:

Basalt ingredient is silica, 3 oxidation 2 aluminium, ferric oxide, calcium oxide, magnesium oxide, which silica content , about forty-five percent to 50 or so. Basalt color, more common for black, black, brown or dark green. Because of its dense texture, the proportion of it than general granite, limestone, sandstone and shale are heavy. Basalt, the production of "cast stone" good raw materials. "Cast stone" is the basalt after melting casting, crystallization processing, annealing and become material. It is larger than alloy steel hard and wear resistant, corrosion resistance than lead and rubber. Basalt is still in a cast steel advanced technology, which has a "lubricant" role, can prolong cast film life. At the same time, basalt can smoke into glass wool, than ordinary glass wool cloth alkali resistance is strong, high temperature resistant performance is good. Basalt is repair of highway, railway, airport runway in the stone of the best material, it has the compressive resistance, crushing value is low, the corrosion resistance is strong, asphalt adhesivity, is the development of railway transportation and highway transport best cornerstone.

Basalt powder grinder;Basalt micro powder grinder, powder milling machine is for super-fine grinding materials with hardness less than 6 in Moh‘s scale and humidity less than 6 percent such as kaolin, limestone, basalt, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, carbon black, diatomite, graphite, alunite, fluorite, potassium feldspar, phosphorite, pigment, up to 200 kinds. The granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.005mm), and the capacity (ton/hour) ranges from 0.4T/H to 7.5T/H depending on the final size and the grinding materials.

Model and technical data of Basalt powder grinder;Basalt micro powder grinder, powder milling machine:

|

Model |

HGM80 |

HGM90 |

HGM100 |

HGM100A |

HGM125 |

|

Ring Diameter(mm) |

800 |

900 |

1000 |

1000 |

1250 |

|

Ring Number/pcs |

3 |

3-4 |

3-4 |

4 |

4 |

|

Roller Number/pcs |

21 |

24-32 |

27-36 |

27-36 |

40-44 |

|

Main Shaft Speed/r. p. min |

230-240 |

200-220 |

180-200 |

180-200 |

135-155 |

|

Input Size/mm |

≦15 |

||||

|

Finished Size/um |

5-47(325-3000) |

||||

|

Capacity t/h |

0.4-4.5 |

0.4-5.5 |

0.4-6.5 |

0.4-7.5 |

0.7-10 |

|

Outlet Size L*W*H/m |

13.9*4*6.2 |

14.7*4.8*7.2 |

18*4.6*8.6 |

18*4.6*8.6 |

14*9*10 |

Note:This specification is just referencing, any changes are subject to the products.

Features of Basalt powder grinder;Basalt micro powder grinder, powder milling machine :

1. High efficiency

Under the same final size and power, the product capacity of Basalt powder grinder;Basalt micro powder grinder, powder milling machine is twice than jet mill and agitation mill.

2. Longer lifetime of spare parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical shaft impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability:

There are no rolling bearings and bolts in grinding cavity, so problems caused by bolts shedding or wear of bearings and seal components will never happen.

4. High fineness of products

The product fineness can reach D97≤5μm.

5. Environment friendly

The application of pulse dust collector and muffler reduce the pollution and noise of the dust, which has reached national environment protection standard.