Feldspar powder making machine—Feldspar powder grinder series. Shanghai clirik machinery co., LTD. Feldspar powder grinder series is the new type mining equipment for making micro powders, fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, and so on. There are five types of Shanghai CLIRIK HGM series Feldspar powder grinder series, they are HGM80, HGM90, HGM100, HGM100A and HGM125. The finished production fineness can be reached 300meshes~3000meshes, 5-47 micron. The capacity (ton/hour) ranges from 0.4T/H to 12T/H.

Feldspar is the floorboard family of feldspar minerals, it is a kind of common calcium, potassium and sodium aluminum silicate kind of rock forming minerals. Feldspar contains calcium, sodium, potassium aluminum silicate minerals, it has a lot of kinds, such as sodium feldspar, calcium feldspar, barium feldspar, barium ice feldspar, microcline, potash feldspar, through feldspar, etc. They all have glass luster, color variety, a colorless, white, yellow, pink, green, gray, black and so on. Feldspar's main purpose is to make ceramics and enamel, glass raw materials, abrasive abrasive, etc., also can make potash fertilizer. Feldspar powder grinder series select CLIRIK!

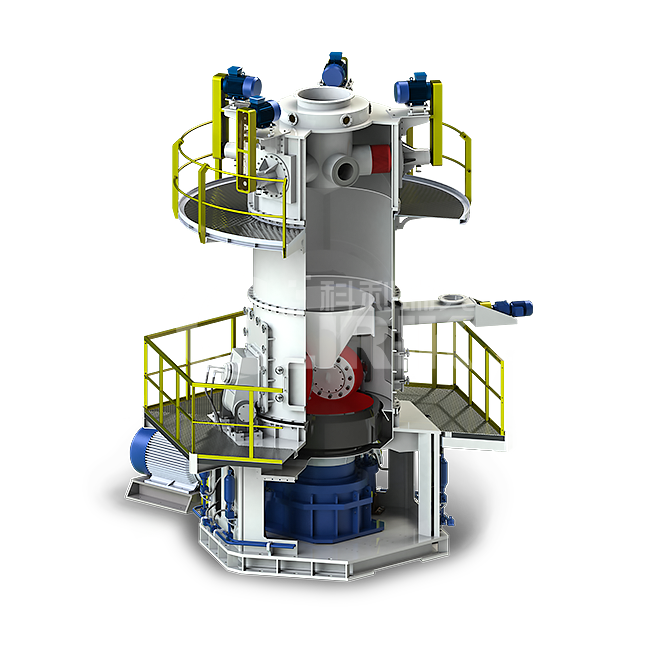

Main Components of Feldspar powder grinder series:

HGM series Feldspar powder grinder series mainly consist of main unit, classifier, dust cleaner, powder collector, blower, muffler, hammer crusher (can be replaced by jaw crusher), bucket elevator, sound-proof room, storage hopper, vibrating feeder and so on.

Technical data of Feldspar powder grinder series :

There are five models of our Feldspar powder grinder series: HGM80(HGM 8021), HGM90(HGM9024), HGM100(HGM10027), HGM100A( HGM10036),and the new type HGM125. The detailed specification and technical data of our Feldspar powder grinder series are as below:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Note: This specification is just referencing, any changes are subject to the products.

Features and advantages of Feldspar powder grinder series:

● High Efficiency

Under the same finished final size and the same motor power, the capacity of Feldspar powder grinder series is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

● Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

● High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

● High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

●Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

●Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.