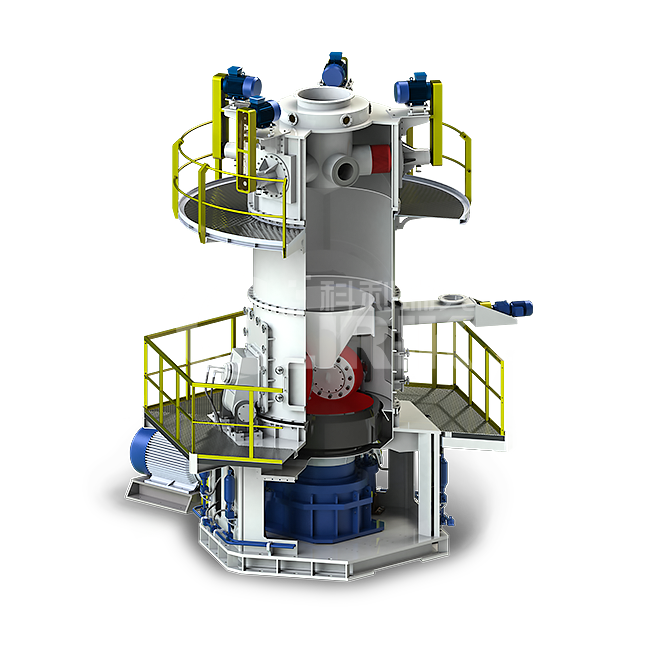

Production Line Configuration of Marble powder grinder machine; Marble powder grinder series:

The whole set HGM Marble powder grinder machine; Marble powder grinder series consists of hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems

Features and advantages of Marble powder grinder machine; Marble powder grinder series:

l、 High efficiency

Under the same finished final size and the same motor power, the capacity of Marble powder grinder machine; Marble powder grinder series is twice as much as jet mill, mixing grinder and ball mill.

2、Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

3、High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4、 High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≦5um.

5、Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

Marble also called Marble stone, is the name of the commodity, not petrology definition, because of its abundant in yunnan Dali and gets its name. Marble is mainly composed of calcite, limestone, serpentine and dolomite composition, its composition with calcium carbonate is given priority to, about 50% above. Marble is mainly used for processing into various shape material, plate, building metope, ground, Taiwan, column, still often used in memorial buildings such as tablet, tower, statues, etc materials. Marble can also carved crafts, stationery, lamps and lanterns, utensils and so on practical works of art. Marble can be used in the coatings, plastics, rubber, etc of the packing.

Marble powder grinded by Marble powder grinder machine; Marble powder grinder series can be used in more areas. So CLIRIK engineer will introduce CLIRIK Marble powder grinder machine; Marble powder grinder series to you.

Technical data of Marble powder grinder machine; Marble powder grinder series:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Note: This specification is just referencing, any changes are subject to the products.

Shanghai clirik machinery co., LTD.

Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machine. please do not hesitate to contact us.

Phone: 0086-21-20236178;86-18918057603

There are five types of Shanghai CLIRIK HGM series Marble powder grinder machine; Marble powder grinder series, they are HGM80 (HGM8021), HGM90 (HGM9024), HGM100 (HGM10027), HGM100A (HGM10036) and the new type HGM125.

Features and advantages of Marble powder grinder machine; Marble powder grinder series:

l、 High efficiency

Under the same finished final size and the same motor power, the capacity of Marble powder grinder machine; Marble powder grinder series is twice as much as jet mill, mixing grinder and ball mill.

2、Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

3、High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4、 High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≦5um.

5、Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

Contact person: lily wang

Email:sales@clirik.com; lilywang@clirik.com

Online consulting: http://www.saico.net ;http://www.grinding-equip.com;

http://www.powder-grinder.com;http://www.powder-mill.net;http://www.fine-mill.net

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.