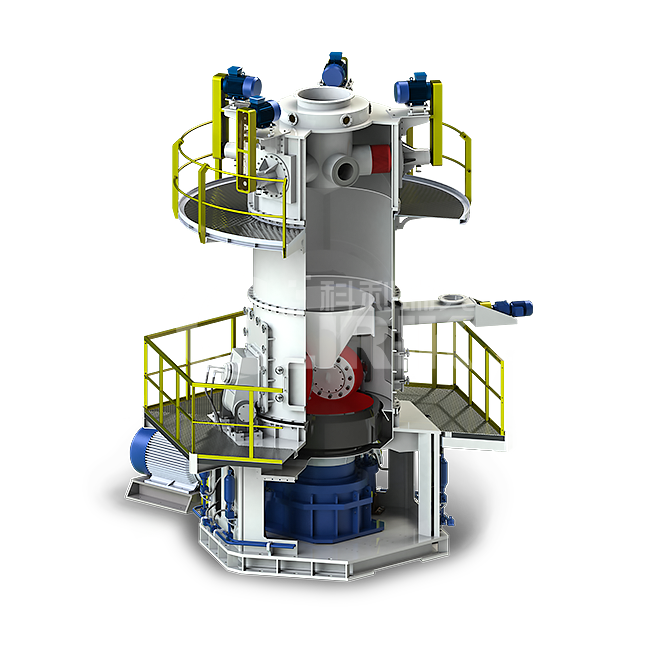

Diatomaceous earth powder grinder machine; Diatomite micro powder grinder:

Diatomaceous earth powder grinder machine; Diatomite micro powder grinder is designed by our R&D department on the basis of multiple innovation and testing. It has been proved by thousands of customers that our machine has outstanding features, stable quality, easy operation and maintenance. It is the ideal equipment for fine powder milling.

Diatomaceous earth powder grinder machine; Diatomite micro powder grinder granularity (or final size) of the finished products can be freely adjusted between 325-3000meshes (0.045-0.0057mm), and the capacity (ton/hour) ranges from 0.4T/H to 12T/H.

Diatomite is also called diatomaceous earth, infusorial earth. Diatomite is a siliceous rock, mainly distributed in China, the United States, Denmark, France, the Soviet Union, Romania and other countries. Diatomite reserves in China is 320 million tons and prospective reserves of over 20 billion tons, mainly concentrated in the eastern and northeastern region. Diatomite processing we have Diatomaceous earth powder grinder machine; Diatomite micro powder grinder. Diatomite is considered to be a good cost-effective powder products with extinction, has large international paint manufacturer as specified supplies, and are widely used in latex paint, interior and exterior paint, alkyd paint and poly ester paint and other coatings systems, especially suitable for the production of architectural coatings. Application of coatings, paints, balanced control coating surface gloss, increased abrasion resistance and scratch resistance of the coating, dehumidification, deodorization, but also purify the air, noise, water and insulation, permeability good features.

Shanghai clirik machinery co., LTD.

Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machine.please do not hesitate to contact us.

Phone: 0086-21-20236178;86-18918057603

Contact person: lily wang

Email:sales@clirik.com; lilywang@clirik.com

Online consulting: http://www.saico.net ;http://www.grinding-equip.com;

http://www.powder-grinder.com;http://www.powder-mill.net;http://www.fine-mill.net

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.

Main Specification of Diatomaceous earth powder grinder machine; Diatomite micro powder grinder:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number(layer) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number (piece) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r.p.m.) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size(mm) | ≤20 | ||||

| Finished Size (μm/mesh) |

5-47 (325-2500) |

||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1 -8.5 | 1.5-12 |

|

Overall Dimension (L*W*H, m) |

13.9x4x6.2 | 14.7x4.8x7.2 | 18x4.6x8.6 | 18x4.6x8.6 | 14x9x10.25 |

| Motor Power(KW) | 145-165 | 175-192 | 263 | 263 | 378-408 |

Note: Any changes of technical data shall not be prior advised.

Advantages and features of Diatomaceous earth powder grinder machine; Diatomite micro powder grinder:

● High Efficiency

Under the same finished final size and the same motor power, the capacity of Diatomaceous earth powder grinder machine; Diatomite micro powder grinder is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

● Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

● High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

● High fineness, flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

●Environment-friendly

The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

●Advanced intelligent speed control device

Convenient adjusting, more uniform particle size.